Peter has a legal and regulatory background from working as a food inspector for the Hawaii State Department of Health, Sanitation Branch, and Food and Drug Branch for nine years, and had maintained a Registered Sanitarians License #221. Part of his job duties was food product label review and keeping up to date with weekly revisions in the Code of Federal Regulations.

Experience in the private sector include operating the quality control laboratory at Foremost Dairies and food research and development at the University of Hawaii, developing Malaysian prawn processing and unique measurement of shelf life, freeze-dried tropical fruit juices, etc.,

Food processing is his hobby. His passion for knowledge and food science has led him to read every reference in the back of every textbook he studied while in school. In addition, Peter attends trade shows and reads trade magazines and journals to keep up with the latest food innovation.

In 1981, Peter founded Rib Roaring Recipes, a sole proprietorship doing food manufacturing, marketing, and distribution. He then founded Hawaii's first food processing incubator in 1982, First Commercial Kitchen LLC, which has helped over 200 start-ups, creating over 300 made-in-Hawaii value-added products. His clientele has included single-parent mothers, local chef entrepreneurs, to multinational corporations.

In 1996 he acquired Wing Coffee Company, an import and distribution business in China Town, Oahu, Hawaii. Wing Coffee has been Hawaii's original Kona Coffee gifting brand since 1904. This company has served as the distribution and export arm of First Commercial Kitchen LLC, with service to nationwide retailers on the U.S. mainland and exports to Japan.

Peter has had membership/directorship in the Hawaii Food Manufacturer's Association, Institute of Food Technologist, Better Business Bureau, National Federation of Independent Businesses, Chamber of Commerce of Hawaii, Hawaii Restaurant Association, etc.

Besides consultation on value-added products, Peter has helped clients pass Costco audits, written HACCP plans, and food safety plans.

Peter's passion is food processing and business. Value-added products are his specialty. Starting with building his own processing equipment, manufacturing his first product, and doing all the marketing/distribution himself, he has experience in the food industry from the ground up. He understands the bottlenecks encountered by new companies and consults with them according to their goals. As a result, there has been a zero percent failure rate for First Commercial Kitchen LLC clients.

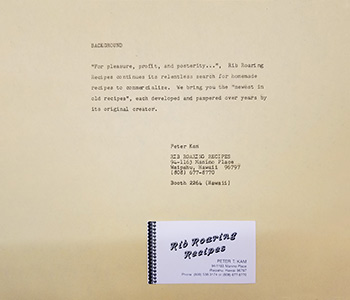

Let us help you - "Commercializing your favorite recipes…for pleasure, profit, and posterity".

What Motivates Us?

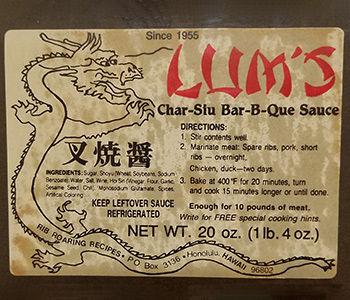

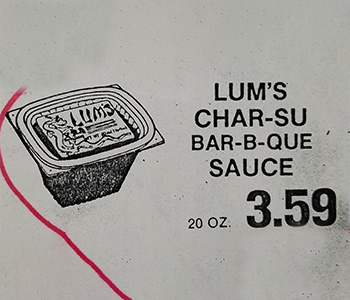

"Commercializing your favorite recipes...for pleasure, profit, and posterity" summarizes what we do. But why do we do it? The motivation is that I still think about my grandmother who used to cook an entire nine course dinner, by herself! It took several days of preparation. I remember how I helped her by frying the oyster rolls. We would look forward to this family get together every year, when near and distant relatives were invited. After she passed, we no longer could enjoy all the good food she use to make for us. In the same light, Lum's Char-Siu Sauce is now preserved for all to enjoy.

How I Got Started in the Value-Added Products Business?

Rib Roaring Recipes was started by Peter Kam in 1981 as a one-person food manufacturing and distribution business later known as First Commercial Kitchen LLC.

A meeting of fate with Mr. Chew On Lum, the owner of Lum's Meat Center, formerly located in Kapahulu, Oahu, Hawaii was the start of this adventure. After Mr. Lum expressed his desire to retire, Peter wanted to preserve this popular family recipe for future generations to enjoy. Otherwise this extraordinary sauce would have been lost forever after the owner passed away. Peter managed to scrape up $2,000, and a downpayment was made to purchase the famous Lum's Char-Siu Sauce recipe. Then, with a limited budget, Peter purchased the necessary items for manufacturing: a spoon, rubber gloves, a plastic baby bathtub, a pitcher, and the most expensive item: a scale. At this early stage, Peter formulated his business philosophy to have the business fully self-sustaining from day one. Not a penny more would be put into the business besides the original $2,000, $1,500 of which went as a downpayment to purchase the recipe.

Peter used the rubber gloves to mix the ingredients and the pitcher to fill the containers. At first, he produced the sauce in the same round, white saimin containers originally used by Mr. Lum, with a small bright orange label on the lid.

Because the sauce was easily squeezed out of this fragile container, he found the next cheapest alternative: a clear deli container and made his own homemade label. This label had a picture of a dragon on it which he sketched. After placing this product in every supermarket on Oahu, he discovered that the characteristic red color of the sauce faded because of exposure to the supermarket lights. He also noticed that the unsightly layering of ingredients became evident when the sauce was filled into a clear container. Fortunately, with his Food Science background, he was able to solve these two problems.

Sometime later, he had enough cash flow to move up to better packaging: a plastic jar with a screw-on lid. And so his mornings were filled with delivering sauce all over the island, and his afternoons occupied with purchasing of ingredients and supplies and manufacturing sauce. Peter would also go to Young Brothers to ship sauce to the outer islands.

After a few years and pondering how to expand this business, he decided to manufacture products for other companies. His first big decision was signing a lease on a new warehouse to be the First Commercial Kitchen, with his first client being a salsa company who had fresh red and green salsas. This was in the mid-eighties.

In 1996, Peter was fortunate to acquire the hundred-year-old import/distribution business known as Wing Coffee Company, which has served as the distribution arm for First Commercial Kitchen LLC. Peter used to buy some ingredients from them and later bottled the Wing Sauces.

Peter is proud to continue expanding on the legacy started by Mr. Lum, the inventor of Lum's Char-Siu Sauce, which started him on this continuing journey. Lum's Char-Siu Sauce will be sold nationwide beginning the summer of 2022. So many food products you enjoy may have been made in this kitchen.

Our new business grew but had very little money, so creative ways to improve production were needed. The first piece of equipment built to increase production was a table to layout an increasing number of filled bottles of sauce. After working on long tables, which were boards on sawhorses, a round turntable was built from various articles found in nearby dumpsters, including old luau table legs, scrap wood and metal, and a purchased 4'x8' sheet of plywood, gear motor, lazy susan bearings, and a rubber wheel which served as a friction drive to rotate the table. This piece of equipment saved on a lot of walking!

After hand capping thousands of bottles, we started using garden gloves, heavier gloves, and a drill press rigged with a cordless drill to help us screw the caps on. Then the first portable cordless capper was built, which enabled us to tighten caps on the bottles as fast as we could feed them.